Magnetic bearings

Premium bearing technology for high speeds

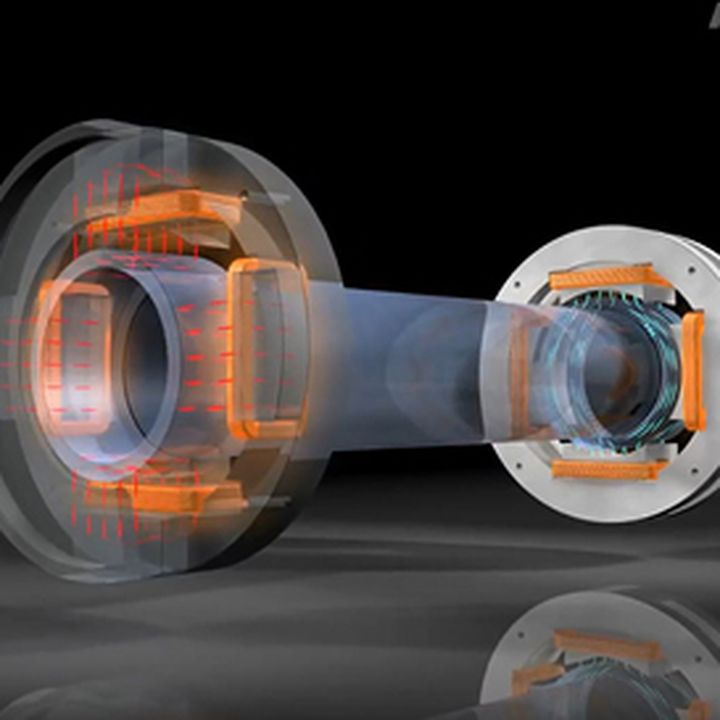

Maintenance-free magnetic bearings for the industrial sector

High-speed applications require high-quality bearing solutions.

Conventional bearing systems are subject to high wear and tear in the upper speed range, or their suitability for cycle-based operation is limited. Magnetic bearings with their contactless technology are non-wearing and maintenance-free. Also, they do not require any lubrication. Active magnetic bearings perfectly complement KEBA’s automated drive solutions and are used in many high-speed applications.

Your benefits at a glance

- Long-standing proven technology

- Industrial-scale robust technology

- Reproducible quality in series processes

- Broad range of process information for condition monitoring

- Energy supply from the drive DC link

Non-wearing

Outstanding availability without maintenance intervals

Efficient

Contactless operation without bearing friction

Flexible

Adaptable to process conditions

Oil-free

Clean processes without lubricants

Overview of our products

Based on our technology portfolio for magnetic bearing systems, we create tailor-made solutions for your specific requirements.

Actuators/sensors

Magnetic bearing components for optimal integration into market-specific drive solutions

- Compact 2-phase and 3-phase bearing technology

- Permanent-magnet-supported bearings for maximum energy efficiency and simple design

- Combined radial and axial bearings ensure short axial design length

- Patented high-resolution position sensors built into the magnetic bearings for maximum accuracy

- Built-in temperature sensors

Control electronics

Highly compact electronics for actuating and controlling the active magnetic bearings

- Control for 5 plus 1 axes

- Available as onboard electronics directly on the motor, or as a cabinet version

- Evaluation of high-resolution position sensors and integration of power electronics in one housing

- Magnetic bearing electronics based on standard servocontroller series

- Easy parameter configuration and control using software tools, bus systems and digital I/Os

- Easy integration into existing communication structures

- Available fully fitted with cables for connection to the magnetic bearing controller

Tools & functions

Easy commissioning and operation

- Commissioning and parameter configuration via a graphic user interface

- Group-based user access rights

- Adaptive unbalance compensation

- Adjustment of bearing damping and stiffness

- Provision of advanced process information via integrated sensor (e.g. vibrations, forces)

- Mains support operation for safe shutdowns in case of a power failure down to virtually zero speed

Our solution for your applications

Complete drive solutions for high-speed applications

- Optimal solution for blower, compressor, and turbine applications

- Complete drive train for high-speed applications

- Usable as motor or generator with magnetic bearing

- Completely maintenance-free

- Power: up to 300 kW

- Speeds up to 60,000 min-1 (depending on power, pressure ratio, and medium)

- Bearing forces: up 3500 N (axial)

- Impeller not included

- Attached magnetic bearing electronics for easy and low-cost installation

- Built-in water cooling system

Complete solutions for demanding processing tasks

- Magnetic bearing spindle solutions for processing tasks with specific requirements

- Power in the multi-kilowatt range

- Speeds up to 60,000 min-1

- Automatic tool clamping system

- Supports targeted periodic deflections of the shaft position in radial or axial direction

- Built-in minimum quantity lubrication (MQL)

Downloads

This might also interest you

LeviTurb

The most efficient and compact complete solution for magnetic bearing turbo blowers in aeration applications.

KeDrive D3

High-performance drive technology compactly combined. We offer you a fast, scalable and compact all-in-one system.

Motor elements

For synchronous motors and generators: Optimized for high speeds and challenging installation conditions.

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.

Locations

Business Areas

Newsroom

Edge

Chrome

Safari

Firefox